Ingilazi ye-ceramic emhlophe

I-White Glass-Ceramic Ye-Cook Plate Panel, Impahla Yekhishi Yesimanjemanje

I-Kanger Ceramic Glass R&D ngezinto ezikhethekile zengilazi, isici esibaluleke kakhulu sezinto ezibonakalayo ukuthi ingakwazi ukubekezelela ukukhuphuka ngokushesha kwamazinga okushisa afinyelela ku-650 ° C. icutshungulwe ibe ngamasayizi ahlukene, ingilazi ithuthukiswe ngokukhethekile futhi iklanyelwe isitofu sasekhishini.I-permeability yayo kazibuthe kanye ne-thermal conductivity, ukumelana nokushisa okuphezulu, i-gloss enhle, ukuzwa ukuthungwa okubucayi nokushelelayo, ukuguquguquka kwesikhathi eside, ukuguquguquka, ukuhlanzeka okulula, i-stylish and elegant.Ngakho ingilazi ye-Kanger iba inkambi emakethe, ithandwa ngabathengi.Iphaneli yengilazi ye-ceramic esiyicubungulayo ihambisana kakhulu nemvelo, impahla yayo eyinhloko ye-quartz, le nto ayinakushiswa ngokwemvelo.

-

• I-coefficient ye-thermalExpansionis icishe ifinyelele kuziro

• Ukuqina kwezinga lokushisa nokuqina

• Ukuzinza kwemishini kuphezulu -

• I-infrared transmittance yokuthuthukisa uhlelo

• I-conductivity ephansi yokushisa

• Ukumelana nokushaqeka okushisayo

Imininingwane Yemikhiqizo

I-Kanger white glass-ceramic iletha izitayela zemfashini neziwubukhazikhazi emakhishini esimanje.Imibala ehlukene yokuhlobisa ingasetshenziswa ukwenza ngokwezifiso umklamo.Ukuqinisekisa ukuthi umklamo jikelele uyahambisana, uhlelo lombala lwenza umklamo ube nokudala okungenamkhawulo.I-Kanger Ihlanganisa ukuhlakanipha nogqozi kubuchwepheshe besimanje be-microcrystalline izibophezele ekudaleni umqondo wesikhathi esizayo wokuvikelwa kwemvelo, ukuhlinzeka ngamaphakheji womuntu siqu.Ngesici esibaluleke kakhulu sengilazi ye-ceramic ukuthi ingakwazi ukubekezelela ukunyuka okusheshayo kwamazinga okushisa afika ku-750 ℃.Inokusebenza kahle okuphansi kakhulu kokunwetshwa okushisayo, ukungena kahle kazibuthe kanye ne-thermal conductivity, ukumelana nezinga lokushisa okuphezulu, isicwebezelisi esihle, ukuzwa ukuthungwa okuthambile nokushelelayo.Kulula futhi ukuhlanza, non-deformationngemva kokusetshenziswa isikhathi eside.

Isicelo

1) Ipuleti yokupheka yokungenisa/i-infrared: ingilazi ye-ceramic ingathwala ukunyuka okusheshayo kwamazinga okushisa afika ku-650 ℃.Ine-coefficient ephansi kakhulu yokwandisa okushisayo.Inokungena kukazibuthe okuphelele kanye ne-thermal conductivity, ukumelana nokushisa okuphezulu, isicwebezelisi esihle, ukuzwa ukuthungwa okuthambile nokushelelayo, ukuguquguquka kokusetshenziswa kwesikhathi eside, ukungaguquki, ukuhlanzeka kalula.

2) Indawo yokupheka yegesi/Iphaneli yesitofu esihlanganisiwe: Ine-coefficient ephansi kakhulu yokwanda okushisayo kanye nokumelana nokushaqeka okuhle kakhulu okushisayo, futhi ingacutshungulwa ngosayizi abahlukene, ingilazi ethuthukiswe ngokukhethekile futhi eyenzelwe isitofu sasekhishini.

3) Imishini yokushisisa: amapaneli okushisa, izifudumezi ze-infrared, amaphaneli okugeza okugeza okungabonakali, ama-heater panel, kanye nemikhiqizo emisha efana nemidwebo yokushisisa.

I-4) Ukunakekelwa kwezokwelapha kanye nezempilo: Amaphaneli ensimbi ye-infrared physiotherapy, amaphaneli e-pedicure, amaphaneli okushisa e-infrared, amaphaneli okushisa ebhodwe lezempilo, ama-coasters okunakekelwa kwezempilo kanye neminye imikhiqizo.

5) Imishini yasendlini: amaphaneli ohhavini bemicrowave, ama-grill, ohhavini, izipheki zelayisi, imishini yekhofi nokunye.

Ukucubungula Ubuchwepheshe

Ukubuka konke kobukhulu: amaphaneli ayisicaba ayisikwe ngosayizi

| Ubukhulu | Ubude obujwayelekile | Ububanzi obujwayelekile |

| 4 mm | 50-1000 mm | 50-600 mm |

| 5 mm | 50-1000 mm | 50-600 mm |

| 6 mm | 50-1000 mm | 50-600 mm |

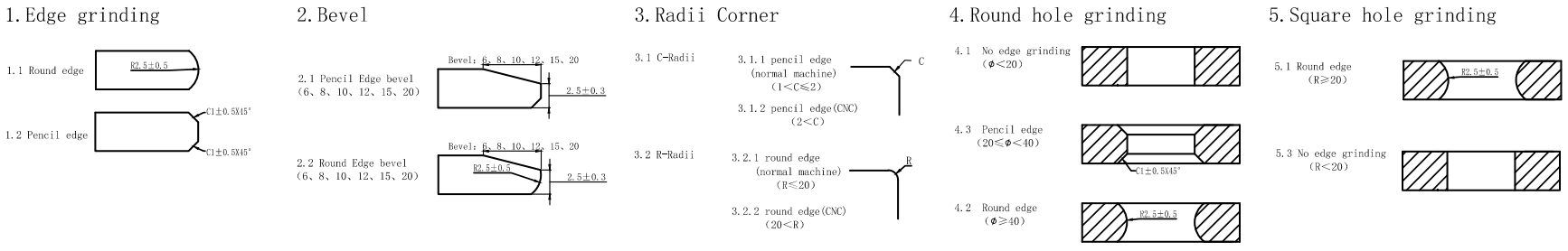

Ukugaya Amaphrofayili

Izindlela Zokucubungula

1. Ukunquma

2. Ukubhakuzisa, ukukhanga, ukupholisha

3. Ukusika amanzi, ukubhoboza

4. Ukuphrinta, ukuhlobisa, ama-decals

5. Ukugqoka

Inqubo Yokukhiqiza

Ukugeleza Kwenqubo 1

I-Row material—Molding—Annealing Furnace—Crystallization—Ukuhlolwa Kwekhwalithi

Ukugeleza Kwenqubo2

Izinto zomugqa—Molding—Annealing Furnace—Crystallization—Polishing—Quality Inspection

Ukugeleza Kwenqubo3

Cutting—Flanging, chamfering—Print—Final Production Inspection—Package—Delivery