Dub ceramic iav

Kub Kub Dub Kub Resistant Induction iav Cooktop

Kanger Ceramic Iav R & D los ntawm cov khoom siv iav tshwj xeeb, qhov tseem ceeb tshaj plaws ntawm cov khoom siv yog nws tuaj yeem dais qhov kub ntawm qhov kub siab mus txog 750 ° C. yuav ua tiav rau hauv ntau qhov sib txawv, cov iav tshwj xeeb tsim & tsim rau chav ua noj.Nws zoo meej sib nqus permeability thiab thermal conductivity, kub tsis kam, zoo gloss, zoo li muag heev thiab du zoo nkauj, siv sij hawm ntev discoloration, deformation, yooj yim los ntxuav, stylish thiab elegant.Yog li Kanger iav dhau los ua lub hauv paus ntawm kev ua lag luam, nyiam los ntawm cov neeg siv khoom.Cov ceramic iav vaj huam sib luag peb txheej txheem yog ib puag ncig zoo, nws cov khoom tseem ceeb yog quartz, cov khoom no yog inexhaustible nyob rau hauv cov xwm.

-

• Coefficient ntawm thermalExpansionis yuav luag txog xoom

• Zoo kub stability thiab kav ntev

• Mechanical stability siab -

• System optimization infrared transmittance

• Tsawg thermal conductivity

• Zoo thermal shock kuj

Khoom Paub meej

Kanger iav-ceramic cooker vaj huam sib luag tsis tsuas yog coj lub kiv puag ncig rau kev siv tshuab ua noj, tab sis kuj muab kev ua noj ua haus niaj hnub, xis nyob thiab lom zem.

Kanger Integrates kev txawj ntse thiab kev tshoov siab rau niaj hnub microcrystalline technology tau cog lus los tsim lub neej yav tom ntej ib puag ncig tiv thaiv lub neej, muab cov pob khoom tus kheej.Nrog rau qhov tseem ceeb tshaj plaws ntawm cov iav ceramic yog nws tuaj yeem dais qhov nce siab ntawm qhov kub siab txog 750 ℃.Nws muaj qhov ua tau zoo ntawm thermal expansion, zoo meej sib nqus permeability thiab thermal conductivity, kub tsis kam, zoo gloss, xav tias muag heev thiab du zoo nkauj.Nws kuj yog ib qho yooj yim los ntxuav, tsis-deformationtom qab siv mus ntev.

Daim ntawv thov

1) Induction / infrared cooker phaj: lub iav ceramic tuaj yeem dais qhov kub ntawm qhov kub siab mus txog 750 ℃.Nws muaj cov coefficient tsawg heev ntawm thermal expansion.Nws muaj cov hlau nplaum zoo meej permeability thiab thermal conductivity, kub tsis kam, zoo gloss, xav tias muag heev thiab du zoo nkauj, siv sij hawm ntev discoloration, tsis deformation, yooj yim los ntxuav.

2) Gas cooktop / Mixed qhov cub cooktop vaj huam sib luag: Nws muaj cov coefficient tsawg heev ntawm thermal expansion thiab thermal shock kuj zoo heev, thiab tuaj yeem ua tiav rau ntau qhov sib txawv, iav tshwj xeeb tsim & tsim rau chav ua noj qhov cub.

3) Cov khoom siv cua sov: cov cua kub cua sov, cov cua sov infrared, infrared da dej rhaub panels, cua sov vaj huam sib luag, nrog rau cov khoom tshiab xws li cua sov murals.

4) Kev kho mob thiab kev kho mob: Infrared physiotherapy instrument panels, pedicure panels, infrared cua sov panels, noj qab haus huv pot infrared cua sov panels, kev kho mob cua sov coasters thiab lwm yam khoom.

5) Cov khoom siv hauv tsev: panels rau microwave ncu, grills, ncu, mov cookers, kas fes tshuab thiab lwm yam.

Kev Siv Tshuab

Txheej txheem cej luam ntawm qhov ntev: flat cut-rau-size panels

| Thickness | Txheem ntev | Txheem dav |

| 4 hli | 50-1000 hli | 50-600 hli |

| 5 hli | 50-1000 hli | 50-600 hli |

| 6 hli | 50-1000 hli | 50-600 hli |

Sib tsoo Profiles

Txheej txheem txheej txheem

1. Txiav

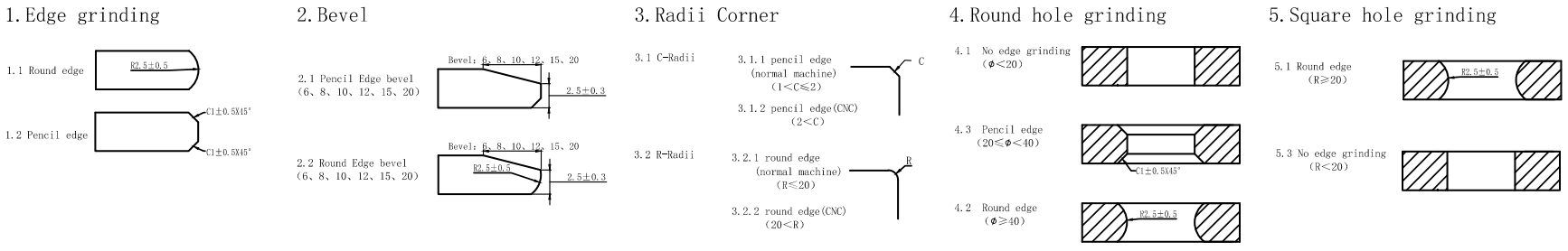

2. Flanging, chamfering, polishing

3. Dej txiav, laum

4. Printing, kho kom zoo nkauj, decals

5. Txheej

Txheej txheem ntau lawm

Txheej Txheem Flow 1

Kab khoom-Molding-Annealing Rauv-Crystalization-Quality Inspection

Txheej Txheem Flow2

Kab khoom-Molding-Annealing rauv-Crystalization-Polishing-Kev soj ntsuam zoo

Txheej Txheem Flow3

Txiav-Flanging, chamfering-Print-Final Production Inspection-Package-Delivery