Khalase e ntšo ea ceramic

Mocheso o Phahameng oa Mocheso o Motšo o Hanyetsang Ho Koaheloa ha Glass Cooktop

Kanger Ceramic Glass R & D ka thepa e khethehileng ea khalase, tšobotsi ea bohlokoa ka ho fetisisa ea thepa ke hore e ka mamella ho phahama ka potlako ha mocheso o phahameng ho fihlela ho 750 ° C. E na le coefficient e tlaase haholo ea ho atolosoa ha mocheso le ho hanyetsa mocheso o babatsehang oa mocheso, 'me e ka khona. e ka sebetsoa ka boholo bo fapaneng, khalase e ntlafalitsoeng ka ho khetheha 'me e etselitsoe setofo sa kichineng.Its permeability e phethahetseng ea matla a khoheli le conductivity ea mocheso, ho hanyetsa mocheso o phahameng, gloss e ntle, e ikutloa e le bonolo ebile e boreleli, ho fetoha ha nako e telele, deformation, ho hloekisa habonolo, setaele le bokgabane.Kahoo khalase ea Kanger e fetoha karolo e ka sehloohong ea 'maraka, e ratoang ke bareki.Letlapa la khalase ea ceramic eo re e sebetsanang le tikoloho e ntle haholo, thepa ea eona e ka sehloohong e tala ke quartz, thepa ena e ke ke ea fela ka tlhaho.

-

• Coefficient ea thermalExpansionis e batla e fihla ho zero

• Seliba botsitso ba mocheso le nako e telele

• Botsitso ba mechine bo phahame -

• Phetiso ea infrared ea sistimi

• Low mogote conductivity

• Hantle mocheso ho tsosoa ha mocheso

Lintlha tsa Lihlahisoa

Kanger glass-ceramic cooker panel ha e tlise phetoho ea theknoloji ea ho pheha feela, empa hape e fana ka phihlelo ea sejoale-joale, e phutholohileng le ea boikhathollo.

Kanger E kopanya bohlale le khothatso ho theknoloji ea sejoale-joale ea microcrystalline e ikemiselitse ho theha mohopolo oa bophelo ba ts'ireletso ea tikoloho, ho fana ka liphutheloana tse ikhethileng.Ka tšobotsi ea bohlokoa ka ho fetisisa ea khalase ea ceramic ke hore e khona ho mamella ho nyoloha ka potlako ha mocheso o phahameng ho fihlela ho 750 ℃.E na le ts'ebetso e tlase haholo ea katoloso ea mocheso, ho kenella ka matla ha makenete le ho tsamaisa mocheso, ho hanyetsa mocheso o phahameng, gloss e ntle, e ikutloa e le bonolo ebile e boreleli.Hape ho bonolo ho hloekisa, eseng deformationka mor'a tšebeliso ea nako e telele.

Kopo

1) Letlapa la induction / infrared cooker: khalase ea ceramic e ka mamella ho nyoloha ka potlako ha mocheso o phahameng ho fihla ho 750 ℃.E na le coefficient e tlase haholo ea katoloso ea mocheso.E na le matla a matla a ho kenella ka matla a khoheli le ho tsamaisa mocheso, ho hanyetsa mocheso o phahameng, ho benya hantle, ho ikutloa e le bonolo ebile e boreleli, 'mala oa tšebeliso ea nako e telele, ho se fetohe, ho bonolo ho e hloekisa.

2) Setofo sa phepelo ea khase / setofo se kopantsoeng sa setofo: E na le coefficient e tlase haholo ea katoloso ea mocheso le ho hanyetsa mocheso o matla haholo, 'me e ka sebetsoa ka boholo bo fapaneng, khalase e ntlafalitsoeng ka ho khetheha le e etselitsoeng setofo sa kichineng.

3) Lisebelisoa tsa ho futhumatsa: liphanele tsa ho futhumatsa, li-heaters tsa infrared, liphanele tsa ho futhumatsa bate ea infrared, liphanele tsa ho futhumatsa, hammoho le lihlahisoa tse ncha tse kang ho futhumatsa liranta.

4) Tlhokomelo ea bongaka le bophelo bo botle: Lisebelisoa tsa lisebelisoa tsa physiotherapy, liphanele tsa pedicure, liphanele tse futhumatsang tsa infrared, lisebelisoa tsa ho futhumatsa tsa pitsa ea bophelo bo botle, li-coasters tsa tlhokomelo ea bophelo bo botle le lihlahisoa tse ling.

5) Lisebelisoa tsa ka tlung: liphanele tsa lionto tsa microwave, li-grill, lionto, liapehi tsa raese, mechini ea kofi le tse ling.

Theknoloji ea ho sebetsa

Kakaretso ea litekanyo: liphanele tse sehiloeng ka boholo

| Botenya | Bolelele bo tloaelehileng | Bophara bo tloaelehileng |

| 4 limilimithara | 50-1000 limilimithara | 50-600 limilimithara |

| 5 limilimithara | 50-1000 limilimithara | 50-600 limilimithara |

| 6 limilimithara | 50-1000 limilimithara | 50-600 limilimithara |

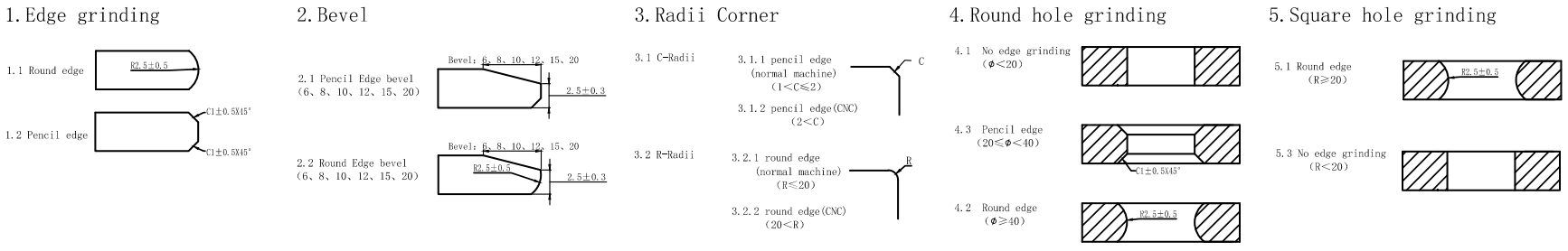

Ho sila Profiles

Mekhoa ea Ts'ebetso

1. Ho fokotsa

2. Ho otlanya, ho khantša, ho bentša

3. Ho khaola metsi, ho phunya

4. Khatiso, mokhabiso, li-decals

5. Ho roala

Mokhoa oa Tlhahiso

Phallo ea Ts'ebetso 1

Thepa ea mela—Molding—Annealing Furnace—Crystallization—Tlhahlobo ea Boleng

Phallo ea Ts'ebetso2

Thepa ea mela—Molding—Annealing Furnace—Crystallization—Polishing—Tlhahlobo ea Boleng

Phallo ea Ts'ebetso3

Cutting—Flanging, chamfering—Printa—Tlhahlobo ea ho Qetela ea Tlhahiso—Package—Delivery