Borosilicate iav

Microwave Cub Borosilicate iav Phaj, Cooker Vaj Huam Sib Luag

Kanger siab borosilicate iav muaj cov yam ntxwv ntawm thermal poob siab tsis kam, tshuaj corrosion kuj, zoo txhua yam khoom, siab kub kev pab cuam thiab siab hardness.Lub pob tshab borosilicate iav qhov rooj tuaj yeem qhia meej txog kev ua noj ntawm cov zaub mov, uas yog qhov kev xaiv zoo tshaj plaws rau lub qhov cub.Peb muab cov kev pabcuam kev cai uas phim cov khoom siv uas twb muaj lawm, kom ntseeg tau tias txhua yam xim zoo ib yam.Peb kuj muab cov txheej txheem cua sov los ua kom qhov cub ua kom muaj zog thiab txo kev siv hluav taws xob.

-

• tsawg nthuav tus nqi

• Zoo kub stability thiab durabilit

• Siab mechanical stability

• Lub teeb kis tau tus mob siab

• Tsawg thermal conductivity

• Muaj tshuaj lom neeg ruaj khov

Khoom Paub meej

Tshaj li 20 xyoo dhau los, Kanger tau tuav txoj haujlwm tseem ceeb hauv kev ua cov iav, ua tsaug rau peb cov kev siv zog tsis tu ncua hauv kev tsim kho tshiab thiab kev tsim kho, uas ua rau peb muab cov neeg siv khoom nrog cov kev daws teeb meem iav tshaj plaws.Txawm nws yog qhov cub qhov rooj sab hauv, sab nrauv. qhov rooj lossis tswj vaj huam sib luag, peb lub iav borosilicate tuaj yeem ua tau raws li cov kev cai tseem ceeb - qhov tseem ceeb tshaj plaws, ua haujlwm ntev, kev nyab xeeb thiab tsim tau raug kho raws li koj tus kheej xav tau, yog li ntxiv qhov kev xav niaj hnub ntawm zam rau cov khoom siv hauv tsev.

Borosilicate iav khoom muaj qhov kub thiab txias tsis kam thiab tawg-pov thawj zog.Zoo heevthermal efficiency, ceev kub dissipation, muaj zog durability thiab ntev kev pab cuam lub neej.Qhov saum npoo ntawm boron iav hauv qab phaj yog smoother thiab kev ntxhib los mos uas tuaj yeem tiv thaiv corrosion ntawm av.Nws muaj kev ua haujlwm siab rau khawb, tshuaj lom neeg (steam, roj ...), yooj yim los ntxuav thiab ua haujlwm zoo heev.Los ntawm qhov zoo nkauj ntawm qhov pom, nws yog qhov tsim nyog rau kev siv chav ua noj, thiab kev yooj yim thiab kev zoo siab tau zoo kawg nkaus nrog ib puag ncig.

Daim ntawv thov

1) Lub qhov rooj qhov cub: Lub qhov rooj pob tshab borosilicate iav tuaj yeem qhia meej txog kev ua noj ntawm cov zaub mov, uas yog qhov kev xaiv zoo tshaj plaws rau lub qhov cub.Peb muab cov kev pabcuam kev cai uas phim cov khoom siv uas twb muaj lawm, kom ntseeg tau tias txhua yam xim zoo ib yam.

2) Microwave hauv qab phaj: Kanger siab borosilicate iav cov khoom muaj qhov kub thiab txias tsis kam thiab tawg-pov thawj cov khoom, thiab tsim nyog siv rau hauv qab phaj ntawm lub qhov cub microwave.Cov phaj hauv qab no ntxiv txhim kho thermal efficiency, thiab muaj cua sov sai sai, muaj zog durability thiab kev pab lub neej ntev.

3) Cooker vaj huam sib luag: haum rau ob-burner, peb-burner, plaub-burner, thiab lwm yam multi-burner cooktop panels.Vim nws qhov kub thiab txias tsis tshua muaj thermal expansion coefficient, lub cooktop vaj huam sib luag yuav tsis khoov thiab deformed, thiab tam sim ntawd kub hloov yuav tsis ua rau lub iav tawg, Nws muaj siab tsis kam mus khawb, tshuaj (steam, roj ...) , yooj yim heev los ntxuav thiab mechanically resistant.Los ntawm qhov zoo nkauj ntawm qhov pom, nws yog qhov tsim nyog rau kev siv chav ua noj, thiab kev yooj yim thiab kev zoo siab tau zoo kawg nkaus nrog ib puag ncig.

Kev Siv Tshuab

Txheej txheem cej luam ntawm qhov ntev: flat cut-rau-size panels

| Thickness | Txheem ntev | Txheem dav |

| 3 hli | 200-1930 hli | 50-980 hli |

| 4 hli | 200-1930 hli | 50-980 hli |

Sib tsoo Profiles

Txheej txheem txheej txheem

1. Txiav

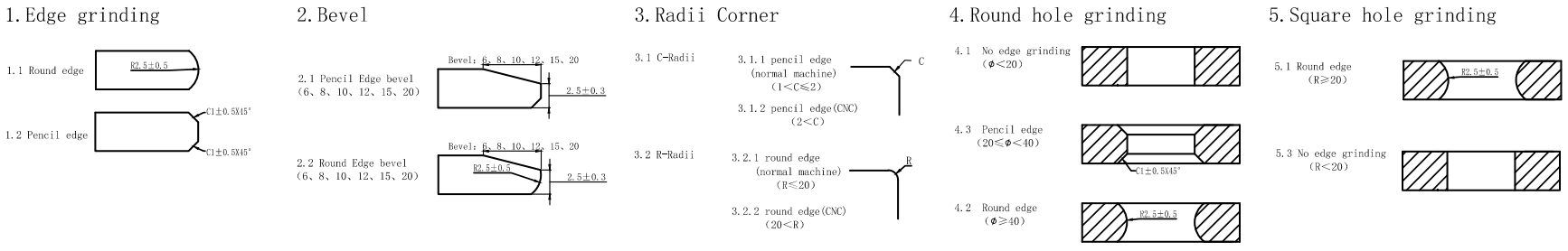

2. Flanging, chamfering, polishing

3. Dej txiav, laum

4. Printing, kho kom zoo nkauj, decals

5. Txheej

Txheej txheem ntau lawm

Txiav-Flanging, chamfering-Print-Final Production Inspection-Package-Delivery