Tempered Glass

Thermal Shock Resisitance Tempared Glass For Household Appliances Panel

Tempered glass is commonly used as interior doors for domestic and professional ovens, and we coat the oven with a low-E coating to maximize energy efficiency and reduce energy consumption. We also provide professional printing services, which can be done on the coated side or the reverse side according to your needs.

-

• low expansion rate

• Good temperature stability and durability

• High mechanical stability

• High light transmission

Products Details

Glass doors and control panels, gas cooker panels, etc. are round in shape, fashionable in appearance, solid and reliable. For manufacturers, we provide fully customizable services matching existing appliances to ensure the overall design and consistent color scheme.

Our tempered glass for hood and stove panel, a variety of internal doors of oven, electrical controllers. After the glass been tempered, the mechanical strength, impact strength and bending strength of the glass can reach 4-5 times than ordinary glass, and withstand severe temperature differences without damage, and the ability to resist variable temperature differences is the same thickness of ordinary float glass 3 times the glass hich greatly increases the life of the equipment. As components that are always visible to the end user, our machining as well as printing and tempering processes must guarantee a high aesthetic quality to bring you a better quality product.

Application

1) Low-E glass: with a low-E coating to maximize energy efficiency and reduce energy consumption of ovens.

2) Switch control panel: capacitive touch control panels, push button touch panels, integrated stove control panels and more. Because the control panel is small in size and requires high precision, As components that are always visible to the end user, our machining as well as printing and tempering processes must guarantee a high aesthetic quality to bring you a better quality product.

3) Hood glass panel: The tempered glass hood panel is high-end and elegant, and it is very beautiful. In terms of cleaning difficulty, the tempered glass panel is better than stainless steel. The tempered glass panel has undergone multi-layer explosion-proof treatment, which can provide you with Safe and security.

4) Integrated stove cooktop panel:The tempered glass panel of the integrated stove has a special central or peripheral groove, in which the stove system can extract cooking steam. We can provide special processes to meet customer needs, and perfectly integrate the extraction system into the stove panel to achieve an innovative kitchen interior.

5) Dishwasher/sterilizer glass panel: Kanger tempered glass provides durability and reliability for dishwashers and sterilization cabinets, which greatly increases the life of the equipment. In addition, we have a high degree of design flexibility and can process the glass according to your requirements, so that the glass panel can be more perfectly integrated into the equipment.

6) Household appliances: It is an ideal new coating decoration material. It has a visual effect of thickness, and the coating is not in direct contact with the outside world. It has excellent performance in aging resistance, friction resistance, scratch resistance, etc., and is easy to clean. , directly corroded by gases or liquids such as acid, alkali, salt, solvent, etc., it is very suitable for air conditioning panels and refrigerator panels, and its colors are diverse and dazzling, which has been recognized by many customers.

Processing Technology

Overview of dimensions: flat cut-to-size panels

| Thickness |

Standard length |

Standard width |

|

3 mm |

200-1930 mm |

50-980 mm |

|

4 mm |

200-1930 mm |

50-980 mm |

|

5 mm |

200-1930 mm |

50-980 mm |

|

6 mm |

200-1930 mm |

50-980 mm |

|

8 mm |

200-1930 mm |

50-980 mm |

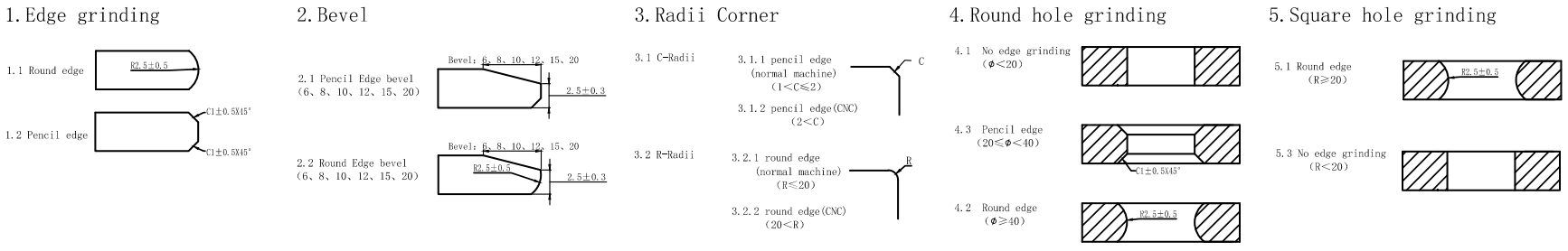

Grinding Profiles

Processing Methods

1. Trimming

2. Flanging,chamfering,polishing

3. Water cutting,drilling

4. Printing, decoration, decals

5. Coating

Production Process

Cutting—Flanging,chamfering—Print—Final Production Inspection—Package—Delivery